Cooling Water Pump Repair

Cooling water pumps play a vital role in maintaining efficient industrial operations, but failures caused by outdated sealing technology can lead to costly downtime and equipment damage. At Reliable Performance and Pump, we specialize in repairing and upgrading cooling water pumps to improve reliability and efficiency.

Let’s Work

Together

Please feel free to send us an email or give us a call!

Enhancing Sulzer ZTT-50-2 Bearing Protection

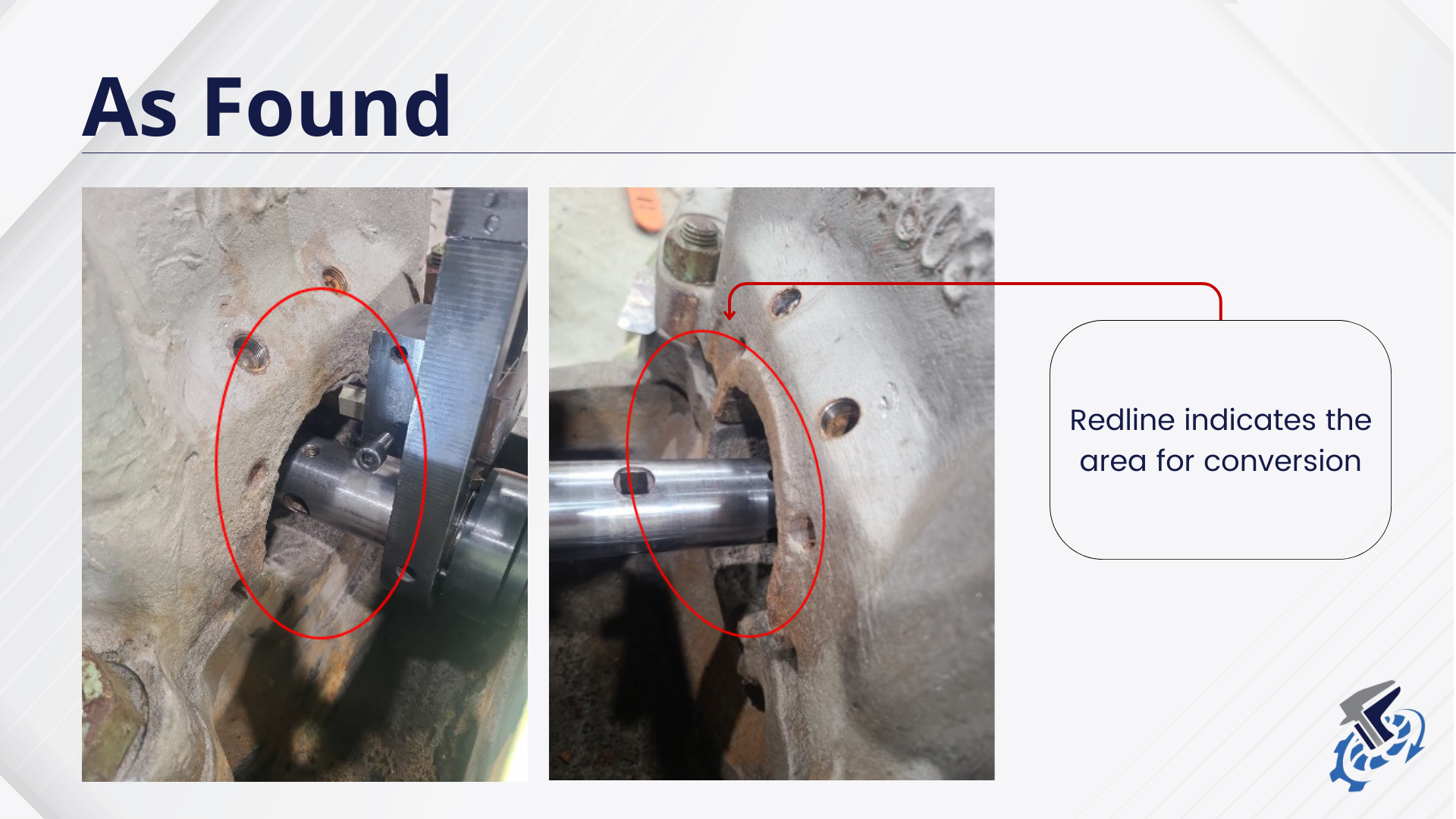

In a recent case study, an OEM standard practice using older technology, called labyrinth seals, which as for the purpose of protecting the lubricating oil from the outside environment at the bearing housing seal at both the IB (inboard) and OB (outboard) bearing housings. This is typical practice and in this case, was being used on a Sulzer ZTT-50-2 (split case, between bearing cooling water application). Labyrinth seals have proven ineffective at protecting the bearing housing environment from outside contamination resulting in water and particulate contamination in the oil. In several cases, there has been catastrophic bearing failure as a result of the contamination for these applications.

Problem

As observed, the labyrinth seals are constructed of a brass ring, with several passages (labyrinth) to make contamination a difficult path to get into the housing. The brass ring is press fit into the bearing housing cover of the housing.

Our Solution

The conversion didn’t cost anymore than what an OEM brass labyrinth ring cost in material cost alone

Inpro isolators are a stock item and lead time is typically less than a week when compared to an OEM labyrinth ring with lead times over several months

Inpro isolators create a positive pressure when in operation and when idle, provide much better protection against environmental contamination, which will result in cleaner oil and a much longer run between failures.

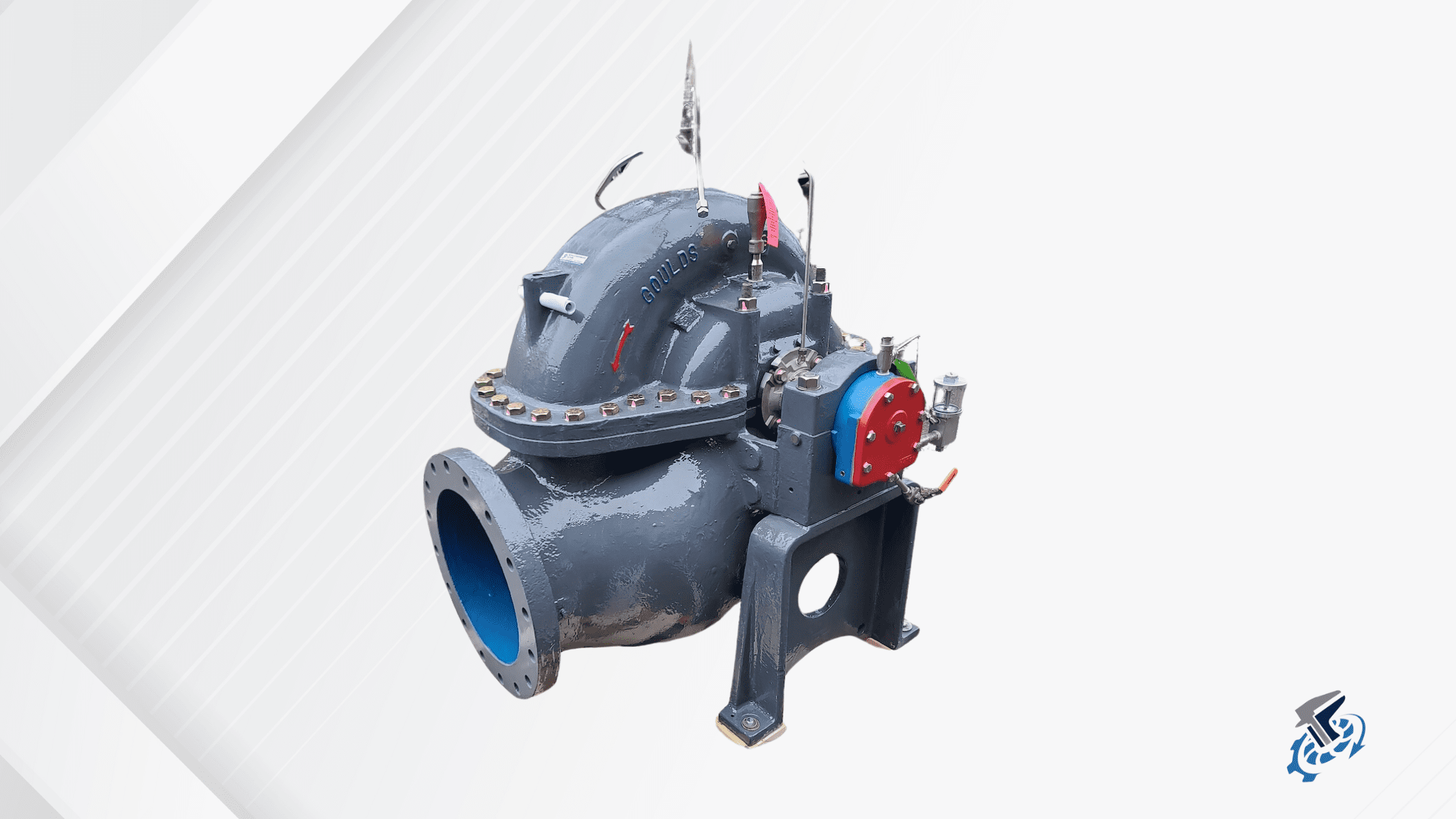

Goulds 3415S Complete Overhaul

Problem

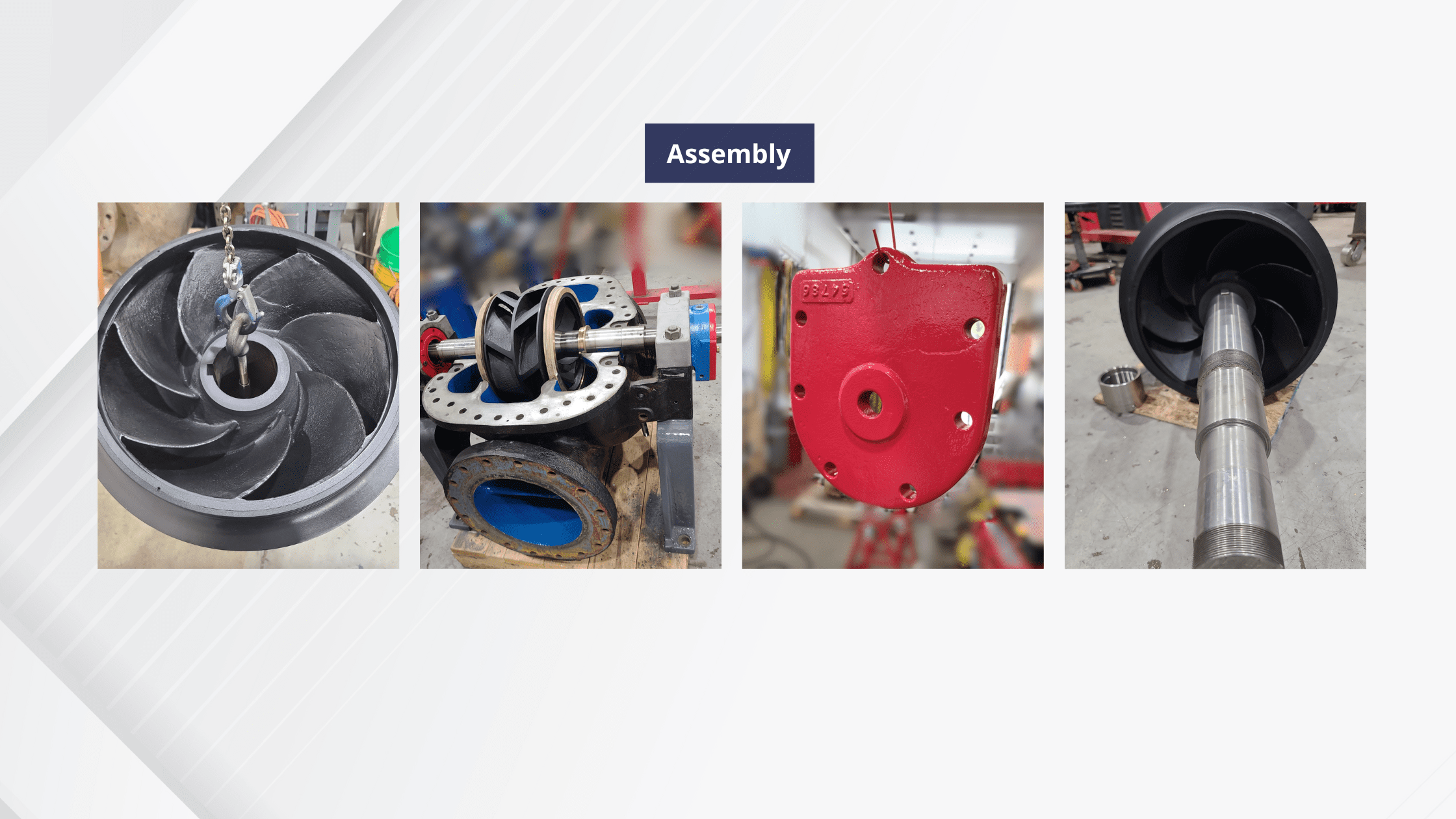

When our client encountered a serious issue with their bearing housing seals, the consequences were severe—catastrophic failures, increased contamination, and the risk of costly replacements. Traditional labyrinth seals had proven ineffective at preventing water and particulate contamination, compromising the performance and longevity of their machinery. Rather than resorting to expensive replacements, our team executed a precision-engineered overhaul, dramatically improving performance and protection.

Identifying the Core Issue

The client’s system relied on labyrinth seals constructed of brass rings, designed to restrict contamination through a complex passage system. However, real-world conditions exposed flaws in this design—oil contamination, environmental infiltration, and premature bearing failures were becoming increasingly common. A proactive solution was essential to prevent further costly downtime.

Innovative Engineering for Maximum Protection

To further enhance reliability and reduce maintenance costs, our overhaul included:

- Positive Pressure Protection – Unlike passive labyrinth seals, the new isolators actively block contaminants, keeping oil cleaner for longer.

- Extended Equipment Lifespan – With improved lubrication integrity, bearing failures are significantly reduced, extending operational uptime.

- Cost-Effective Solution – Avoided a full system replacement, saving the client substantial costs while delivering a superior performance upgrade.

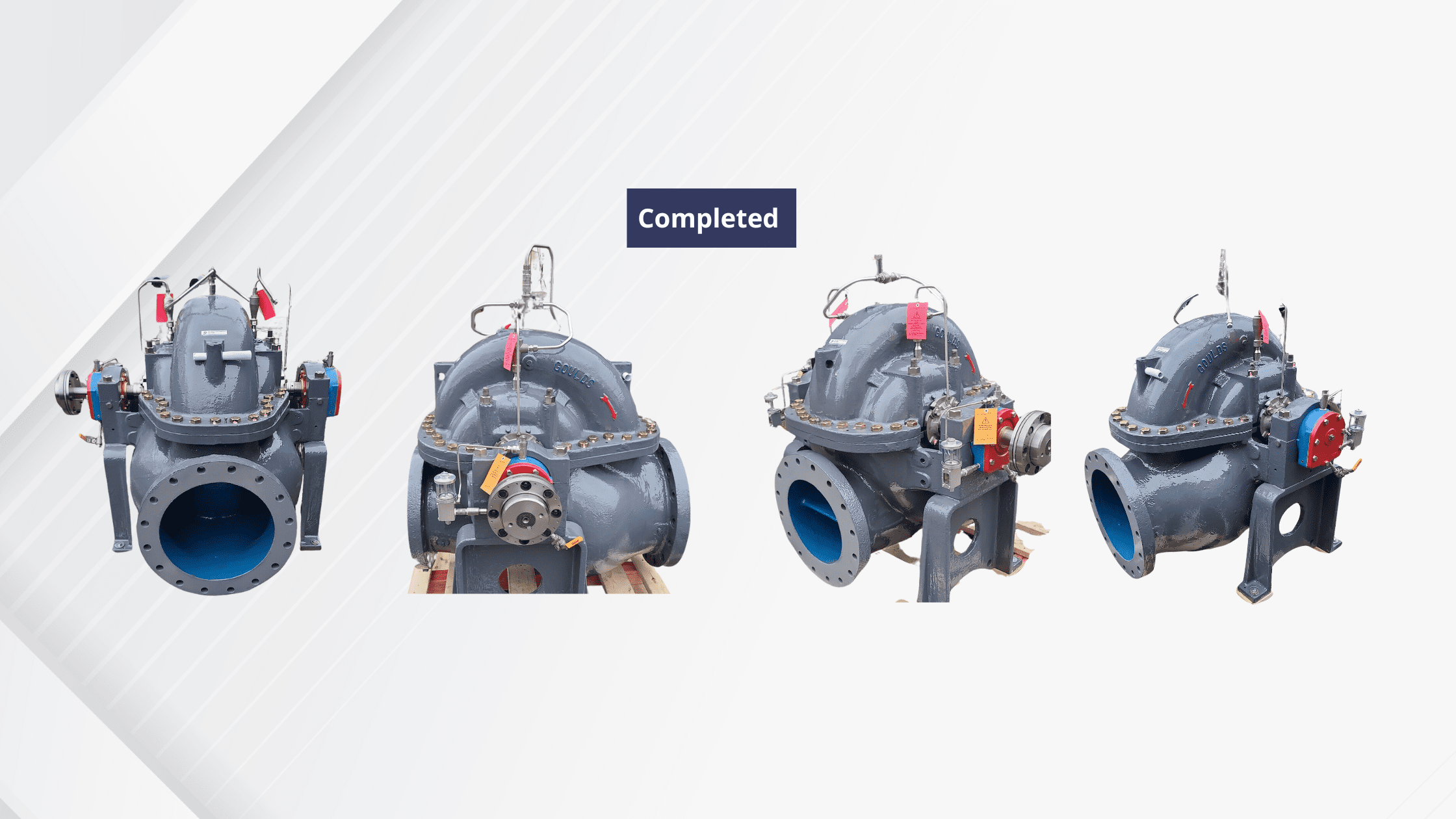

Results that Deliver

By upgrading the sealing technology and optimizing performance, we provided the client with a long-term solution that enhances reliability, minimizes maintenance, and prevents costly failures. Our custom overhaul not only fixed the immediate issue but also future-proofed the equipment, ensuring smooth and efficient operation for years to come.

When critical repairs demand innovation and precision, our team is ready to deliver high-value solutions that maximize equipment performance.

Goulds 3415S Cooling Water Pump

Problem

In the demanding environment of cooling water services, maintaining the integrity and reliability of pumps is crucial. One challenge we encountered involved the Goulds 3415S pump, experiencing chronic leaking and spraying due to packing issues. This problem was further compounded by corrosion and the fouling of surrounding equipment with hard water scale. These issues not only disrupted operations but also required frequent and costly maintenance.

Our Solution

The first step was to eliminate the leakage by replacing the traditional rope packing with a more reliable mechanical seal. This significantly improved the sealing efficiency, preventing leaks and minimizing the risk of corrosion.

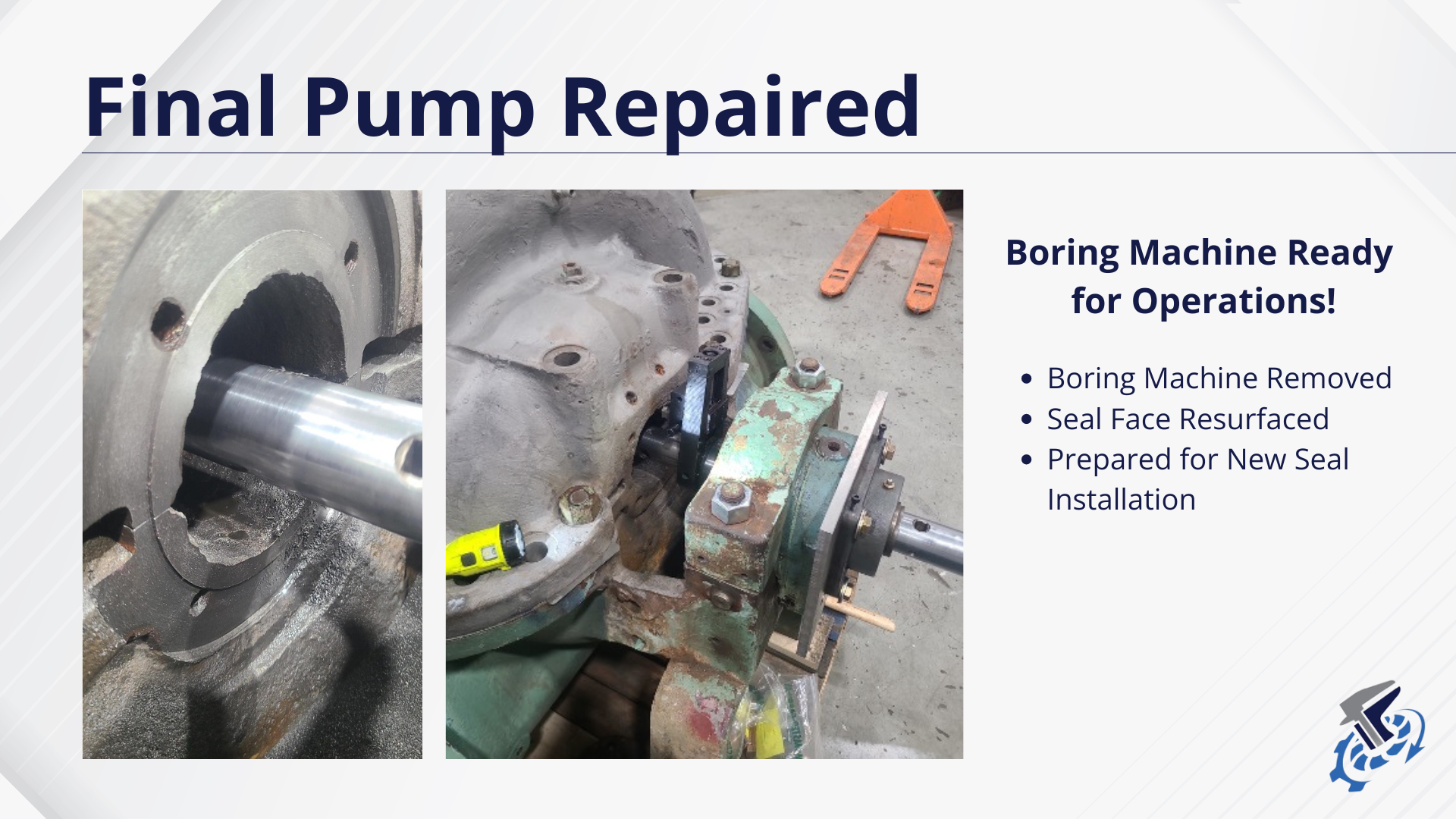

Using line boring tooling, we resurfaced the seal chamber face. This step ensured a perfect fit for the new mechanical seal, enhancing its effectiveness and longevity. Precision resurfacing is crucial in preventing future leaks and maintaining the integrity of the seal.

To streamline future maintenance and ensure consistency, we chose a standard mechanical seal for the conversion. This decision not only simplified inventory management but also ensured that replacement parts would be readily available, reducing downtime and maintenance costs.

At Reliable Performance and Pump, we’re committed to delivering innovative solutions that optimize pump performance and reliability at an affordable cost. This case study on the Goulds 3415S pump exemplifies our dedication to providing repair alternatives, such as upgrading outdated technologies, to ensure our clients benefit from a one-time, cost-effective repair that is better than new!