Pump Repair

Are you tired of the pump shops claiming to have years of experience and can repair pumps but they only know how to replace parts? We have over 40 years of experience with a reliability-focus to repair pumps and other industrial equipment. Our goal is to repair the equipment once and not have it back for repair ever again because the repair was so good. Call us for support on pump repair, reliability improvements and upgrades, troubleshooting and root cause analysis.

- Home

- Pump Repair

Pump Inspection & Maintenance

We specialize in reliability-focused pump and equipment maintenance that focuses on ensuring it meets the right life cycle cost. Contact us to help you with these common pump failure modes:

- Corrosion

- Bearing issues

- Seal leaks

- Worn shafts

- Coupling issues

- Impeller damage

Pump Reverse Engineering

If you’re searching for discontinued, hard to find or long lead time, high cost parts, we can help you by reverse engineering or repairing your existing parts. Instead of starting from scratch, let us help you restore your equipment quickly and affordably to add life. Instead of buying new parts, we can evaluate what it takes to repair or reverse engineer the part to OEM or industry specifications. The final product will be as good or better than new. Call to speak with our technical team to see what options there are for the application.

The benefits of reverse engineering include:

- Supply of obsolete components

- Improved efficiency

- Improved mechanical and hydraulic performance

- Reduced operating and maintenance costs

- Ability to replace parts from any manufacturer

Pump Repair & Overhaul

Buying a new pump can be expensive and there are repair alternatives that can be an in kind replacement or reliability improvements to reduce costs and improve performance and efficiency. Let us be your reliability wingman and repair shop of choice to restore and improve the pump and save you money.

- Process begins with an inspection, OEM / industry specifications and physical measurements

- Each pump gets a complete tear down, written inspection report with specifications, tolerances and measurements with as found data, what the specification is and final, as built. You will rarely find any other pump company doing this!

- Once as found conditions are documented, a quote is submitted comparing the cost of new parts, repaired parts and repair options (when possible) and a separate section for reliability investment modifications to improve performance, efficiency and reliability.

- All repairs are intended to make the part last longer and be stronger than the OEM where practical to save you time, money and the part will last longer.

- Once approved, the repairs proceed and a final as built report is submitted for your mechanical integrity records.

- We are familiar with OSHA Process Safety Management (PSM) and EPA Risk Management Plan (RMP) and know exactly what is required for Mechanical Integrity compliance documentation for your records.

Are your industrial pumps in need of mechanical seal repair or replacement? No matter the industry, make / model or pump, our team can repair the seal or provide a recommendation or repair solution.

- Fully disassemble and clean the pump

- Evaluate the gaskets and seals

- Identify the issue and provide a detailed inspection report

- Estimate total cost of repairs

- Fully repair the equipment

- Deliver the repaired pump parts to your facilities

As part of our value-added reliability service. We can upgrade and modify bearing lip and labyrinth seals to accept Inpro Isolators, which is a significant upgrade reducing the risk of outside contamination getting water, humidity and dirt into the oil or lubricate for a bearing housing.

When evaluating for an upgrade from a lip or labyrinth seal:

- Take measurements and work directly with Inpro Engineering to ensure the right isolator is specified for the job

- Once engineering is complete, drawings will be created and documented for your records

- Isolator will be installed per Industry best practices and an Isolator part number is created so you can continue to purchase from us for future repairs or buy from any Inpro distributor in the future. Our goal is not to lock you into a proprietary design but provide the best possible, long term reliability design for your equipment.

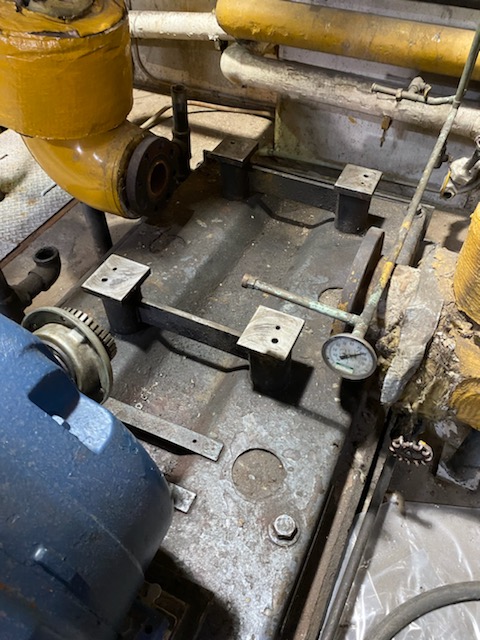

If you have a need for field machining services we can help.

- Field base machining

- Laser alignment

Coatings are used for a variety of pump and industrial equipment repair and performance enhancements and efficiency. Call us to talk about how we can help repair and improve things like:

- Pump wear plates / rear covers

- Pump Impellers

- Pump, turbine and gearbox shafts

- Pump cases (internal and external)

- We prefer to use Enecon ceramic products but have experience with the other manufacturers as well such as Belzona

- In addition to epoxy ceramics, we use Plating, HVOF spray, Hard coatings, Plasma coatings, epoxy paints and others

- Typically adding a coating to a used pump (impeller and case internal) can restore and improve pump performance by 40-50% bringing it back to new or better then new for a fraction of the cost of new parts!!!