Reliability Engineering

Training and subject matter expertise in the following areas:

- Analyzing equipment failure data to identify patterns and trends

- Failure Mode Effect Analysis (FMEA)

- Process Hazard Analysis (HAZOP)

- Layers of Protection Analysis (LOPA)

- Trained in OSHA, DOT and EPA regulations related to General Industry, Transportation of Hazardous materials.

- Process Safety Management (OSHA PSM) and EPA Risk Management Plan (RMP)

- Leading, mentoring or teaching on how to conduct root cause analysis (RCA) using the Cause Mapping method

- Developing and implementing maintenance procedures, specifications, standards, best practices and similar.

- Finding new technologies and processes that can improve equipment performance and reliability

- Developing and implementing training programs for employees, maintenance personnel and reliability / maintenance leaders that are practical, actually get used and cost effective.

- Collaborating across businesses, internal business personnel and departments so that reliability is integrated into all aspects of the organization.

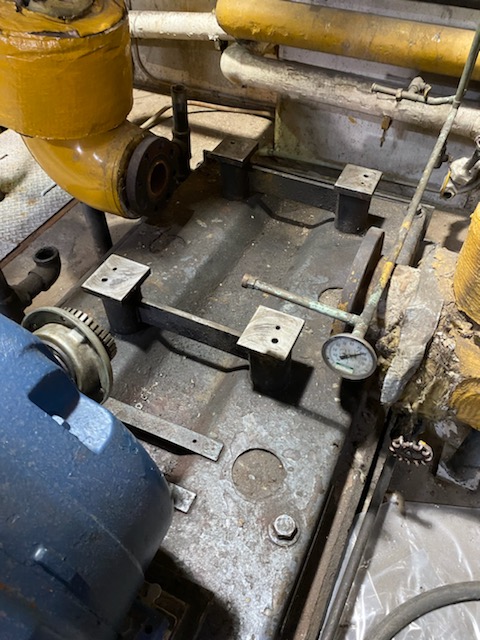

- Field audits or remote capabilities for analysis, support and collaboration

- Experience in Ethanol, Diesel Biofuel, Power Generation, Heating and Cooling Systems for municipalities, Oil Refining, Petro-chemical, General Industry, Foundries, Sheet Rock / Gypsum production, Cellulose Construction Materials and Paper Mills

Transformation (what does this mean?)

Skilled in taking this information and developing comprehensive Reliability Strategies for Production Facilities, Process Systems, Sub-systems, Equipment or to the Component level.The strategy can be right-sized or scaled to be as simple as a time-based Preventative Maintenance operator round or up to including a risk-based economic marginal analysis developed to be used for Leadership to frame up risk, investment capital spending strategies, budgeting, etc.

If you are looking for a program leader, mentorship support for your team, training or field audits or similar we can help with practical, cost-effective experience to support your efforts and provide realistic solutions to problems presented in a way that your leadership will understand to justify the risk position and spending already occurring at the facility.