Rotary Positive Displacement Pumps

We specialize in cost-effective repairs and refurbishments of IMO positive displacement pumps. Using advanced techniques like HVOF carbide coating, we restore components to optimal condition, enhancing efficiency and reliability while significantly reducing lead times and costs.

Let’s Work

Together

Please feel free to send us an email or give us a call!

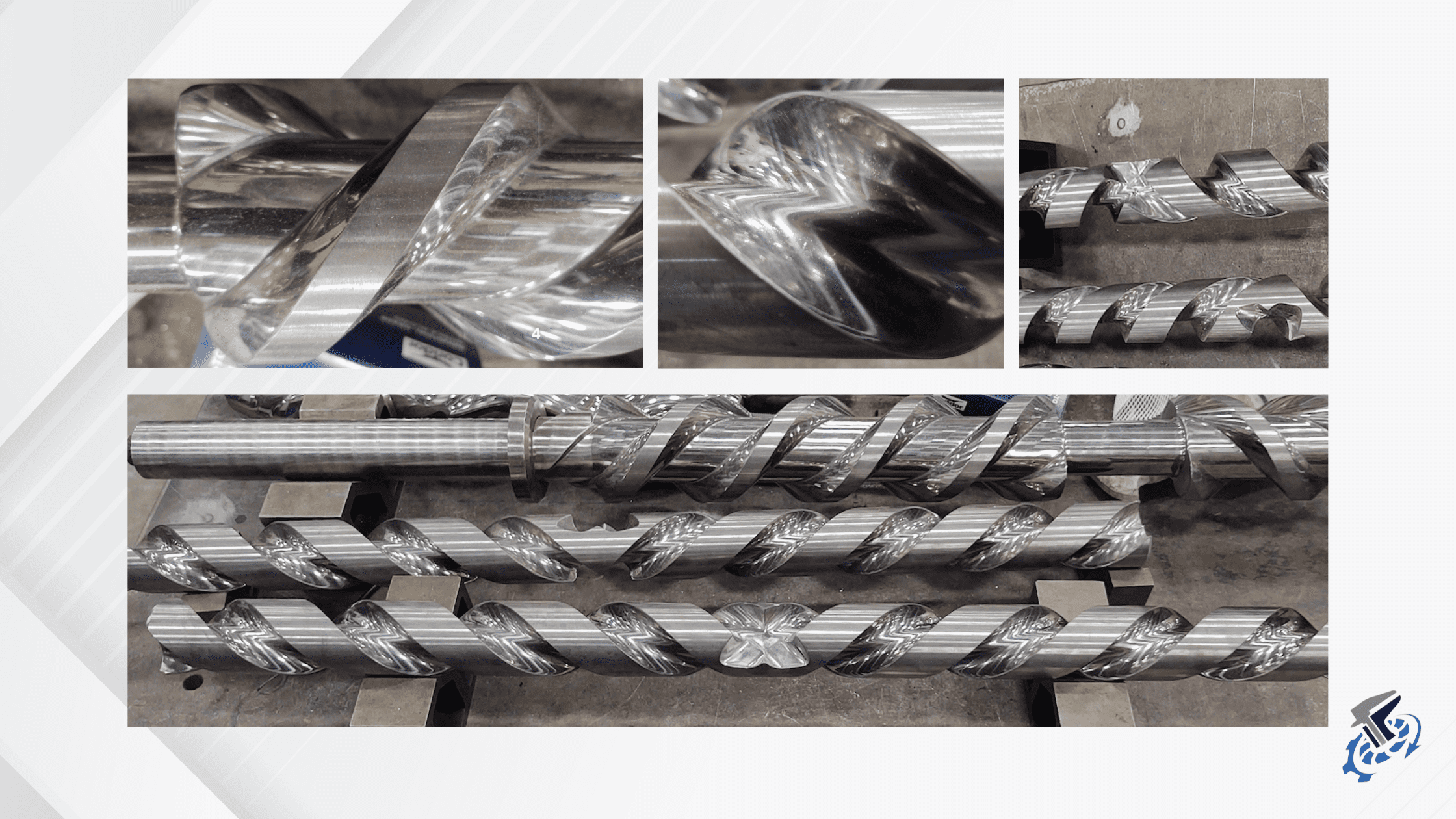

IMO Rotary Positive Displacement Pump Repair

The Challenge

Progressive cavity pumps, including those manufactured by Moyno, are widely used in industries like municipal sewage and wastewater treatment because of their ability to handle high-viscosity and shear-sensitive fluids.

However, maintaining these pumps can be a challenge:

- High Costs and Delays – OEMs typically only offer full repair kits instead of individual parts, driving up costs and increasing wait times.

- Limited Repair Options – OEM repairs are often expensive and slow, leaving operators with limited choices when components wear down or fail.

Our Solution

We offer a cost-effective alternative by using High-Velocity Oxygen Fuel (HVOF) carbide coating technology to repair and refurbish IMO rotary positive displacement pumps to better-than-new condition.

We specialize in repairing and refurbishing OEM pump components using HVOF carbide coating on all wetted and critical fit areas.

One of the key advantages of our solution is the significant improvement in efficiency and reliability. By refurbishing components with superior materials and techniques, we ensure that pumps operate more smoothly and with less energy consumption. This not only reduces operational costs but also extends the lifespan of the pump, leading to fewer failures and less frequent maintenance needs.

Our repair and refurbishment services offer a substantial reduction in lead time and cost compared to OEM options. We quickly and cost-effectively refurbish components, minimizing downtime and maximizing productivity. This efficient turnaround allows our clients to resume normal operations much sooner and at a fraction of the cost of purchasing new components.