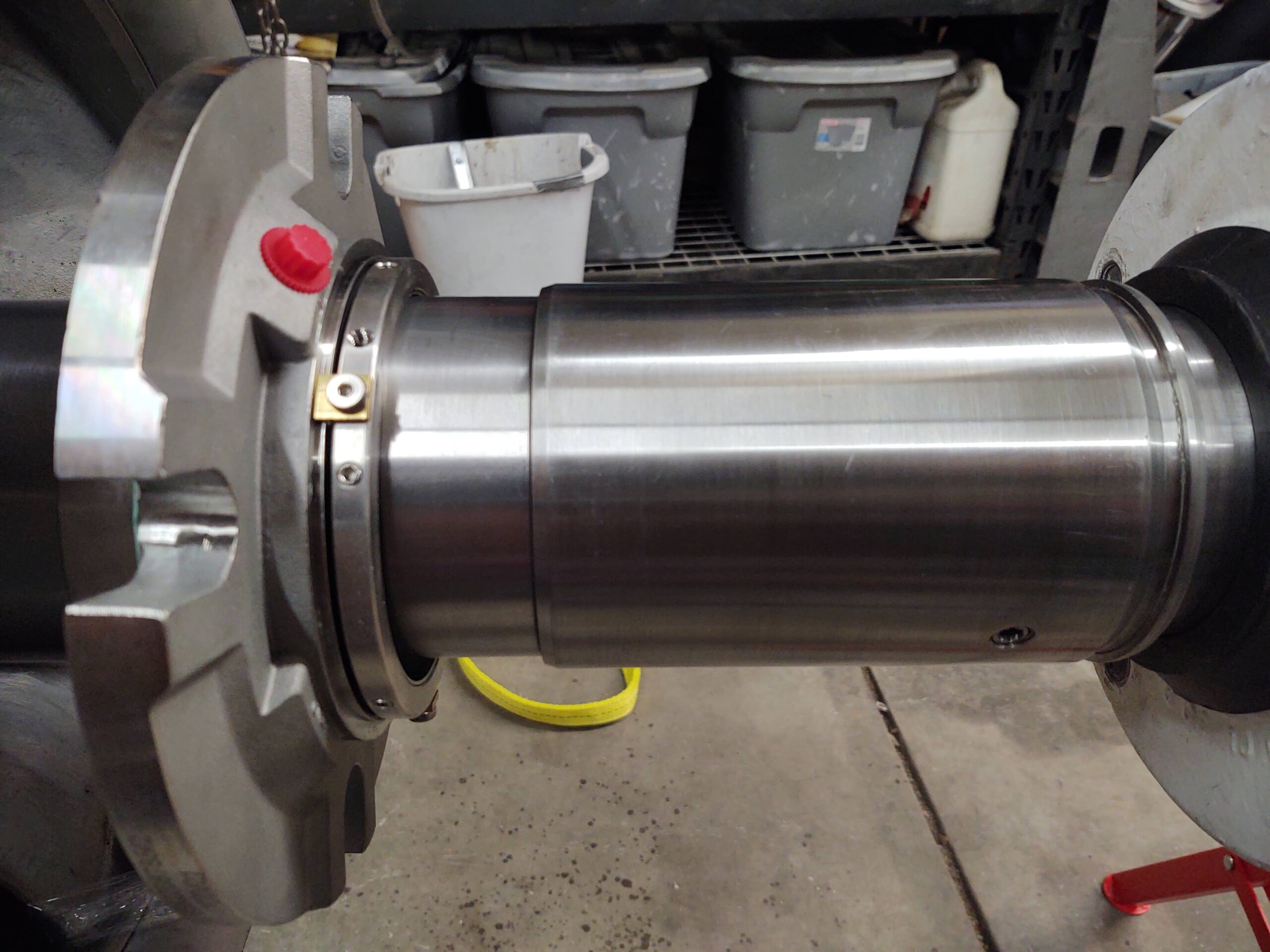

Industrial Shaft Repair

Rotating parts must be well maintained to sustain the operating effectiveness of equipment, avoid costly downtime, and help prevent accidents which could result from equipment failure.

Our skilled team has experience repairing and remanufucturing shafts used across numerous industries. We also offer our experience improving the operating life by offering various coating solutions that can reduce damage due to galling, reduce improve wear resistance on seal surfaces, dynamically balance to reduce vibration and/or improve motor life and efficiencies.

Shaft Repair

Gate Valve Gate Stem

Welding Capabilities

This a process that uses a wire spool to feed wire to the joint and has a bottle of gas that flows from the machine to the welding handle to protect the weld from the air around it.

This a torch that has a gas flowing through it with a non consumable rod made of tungsten that heats the metal and the filler metal is held in the other hand and manually added when needed.

Spot welding is the most commonly used form of resistance welding. Usually it is used to weld various sheet metals with reduced thickness.

( also called STICK or SMAW welding) This welding uses a rod called an electrode that has a powder coating (technically a flux) on it. It burns or melts to create a shield from oxygen. Some rods have filler metal added to the coating to speed up the welding process.

Almost any metal can be welded depending on the process and conditions. Please feel free to call us 952-913-5983 and discuss your project.

Materials/ | Hardness | Bond | Application Data |

Tungsten | 63-66 RC | >10,000 PSI | •Pump seals |

Chrome | 65 RC | >10,000 PSI | •Turbine inner nozzle supports |

Tungsten | 64 RC | >10,000 PSI | •Pump shafts with corrosion |

Materials/ | Hardness | Bond | Application Data |

Cobalt | 50-55 RC | 9500 PSI | •Very dense and well bonded |

Iron | 53 Rb | 7500 PSI | •Excellent for corrosive and sliding wear below 1200°F |

Nickel | 45 Rb | 6000 PSI | •Bond-coat for carbides and ceramics |

Copper | 60 Rb | 4000 PSI | •Exceptionally dense and machinable |

Materials/ | Hardness | Bond | Application Data |

Aluminum | 68 RC | 5000 PSI | •Very Smooth, with high dielectric (600-900 V/Mil) |