Our goal is to build long-term partnerships with our customers focused on win-win outcomes.

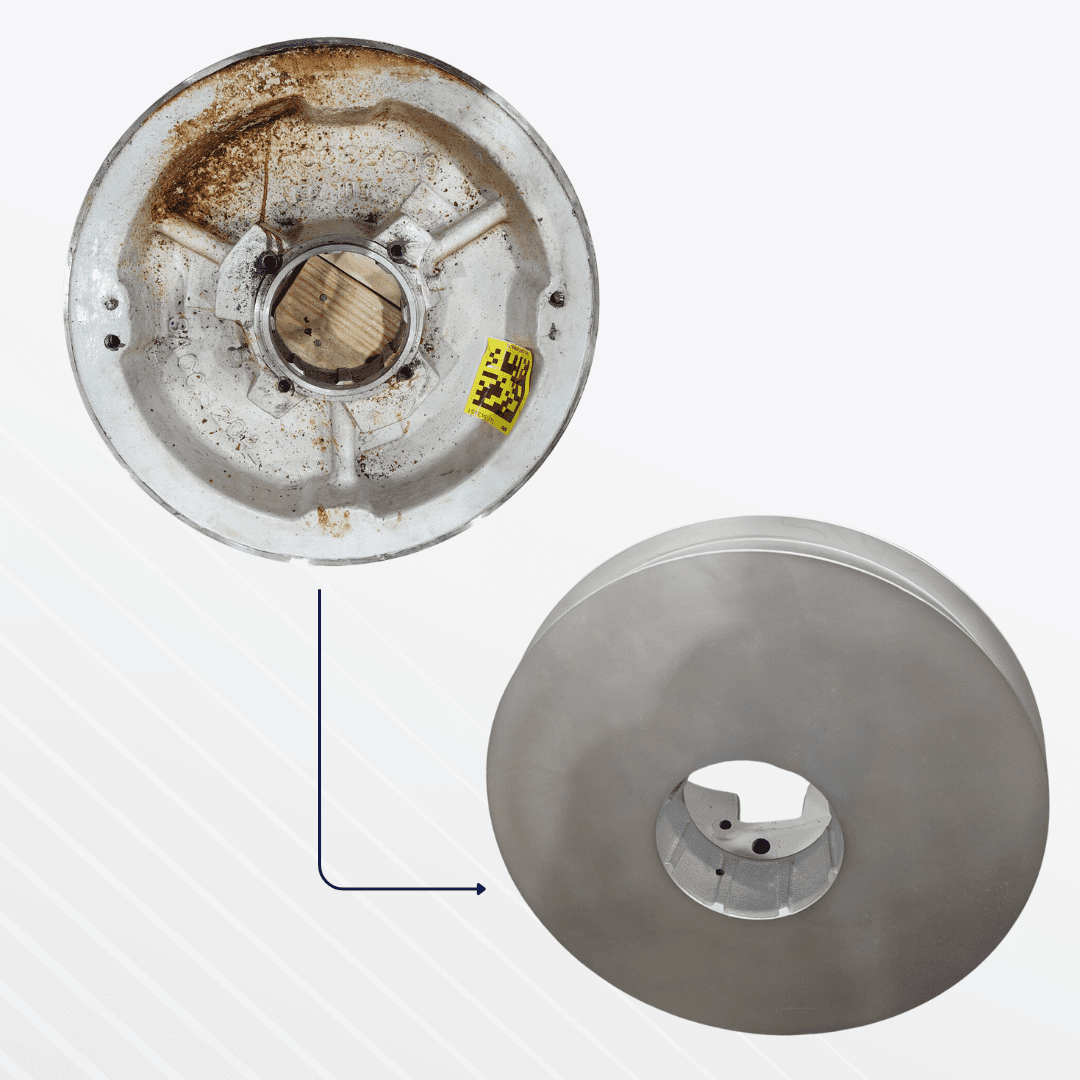

A failed bearing, carbon ring or seal can mean a damaged shaft. Most vendors want to sell you a new shaft at a long lead time and high profit to them. Our goal is to repair shafts with alloy or hard coating so that it’s better than and lasts much longer than new. Our goal is to repair once.

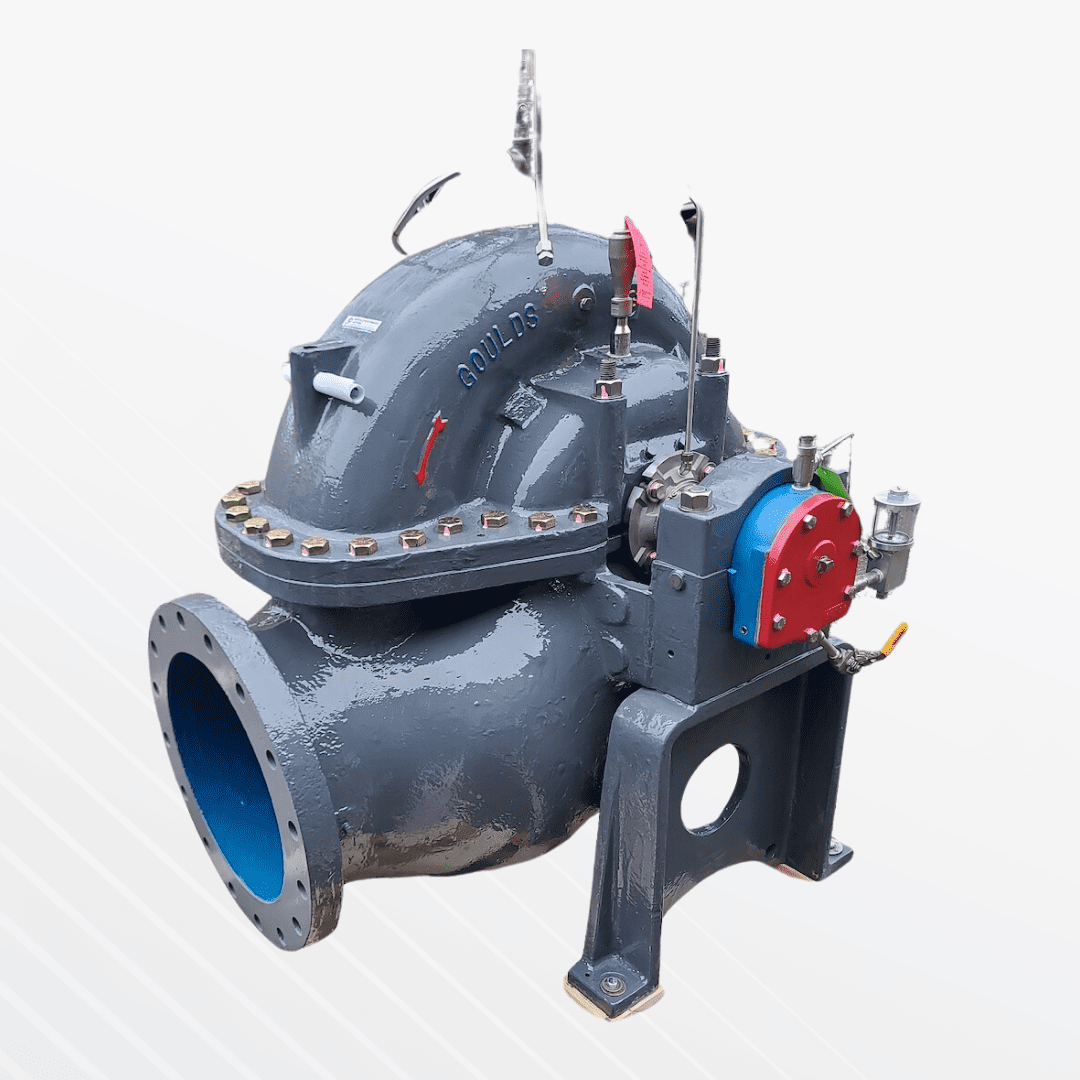

Are you tired of the pump shops claiming to have years of experience and can repair pumps but they only know how to replace parts? We have over 40 years of experience with a reliability-focus to repair pumps and other industrial equipment. Our goal is to repair the equipment once and not have it back for repair ever again because the repair was so good. Call us for support on pump repair, reliability improvements and upgrades, troubleshooting and root cause analysis.

Optimize your industrial equipment’s performance with our reliability engineering expertise. We offer tailored solutions and practical training to keep your operations running smoothly.

Achieve peak performance with our precision balancing services. We specialize in optimizing equipment balance for enhanced efficiency and reliability.

Why use us vs. the competition?

Critical tolerances are measured, documented and compared with industry specifications. Pictures and video are taken as needed and provided to the customer as part of the repair scope to ensure the customer is getting what they pay for: quality work with high integrity. Final Records are provided to the Customer when the job is done, which is required for compliance with OSHA 29CFR1910.119 Process Safety Management, Mechanical Integrity or for your companies Maintenance Records.

Repair Services

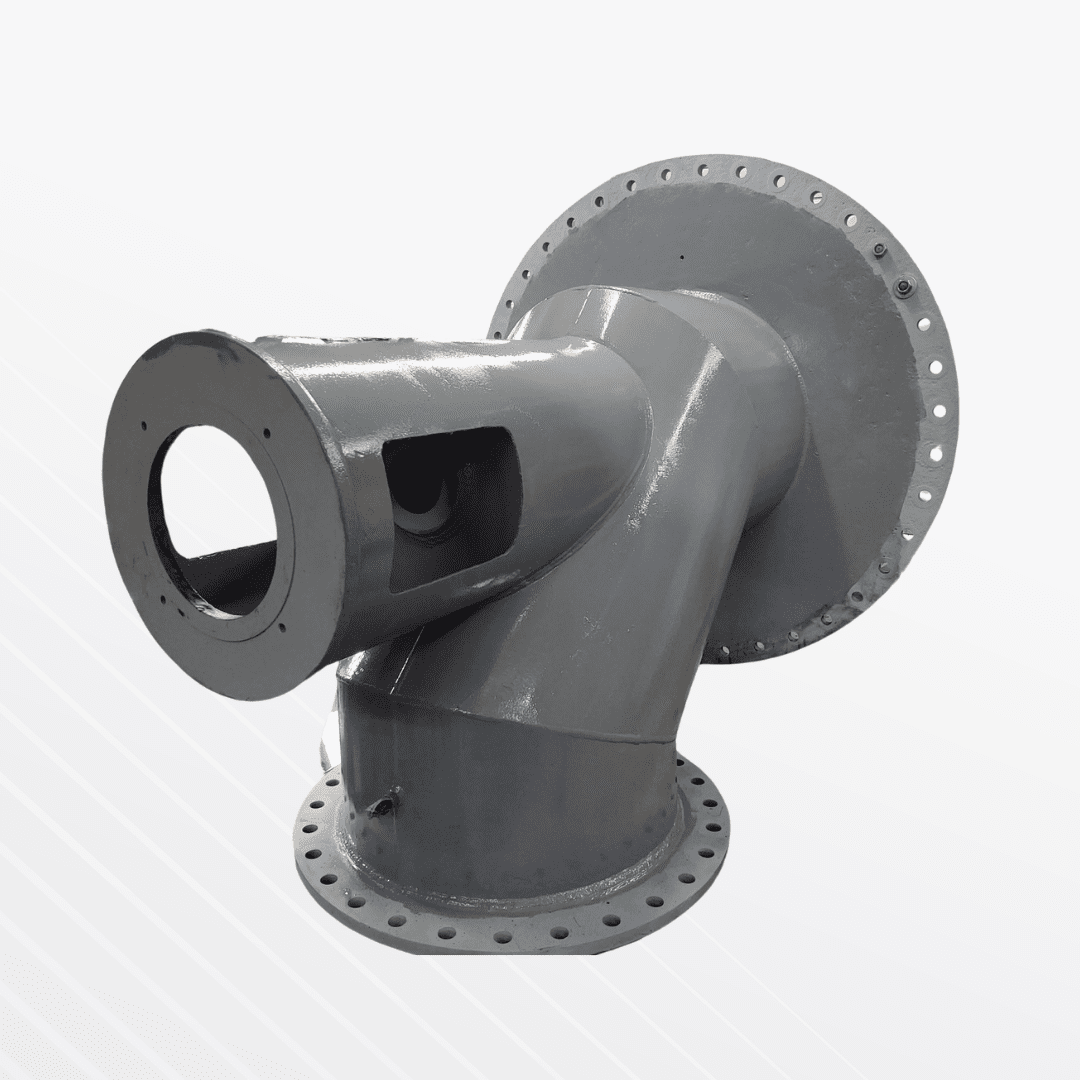

We have over 20 years of experience with API and ANSI pumps. All equipment goes through a thorough inspection, using care, custody and control. Critical tolerances are measured, documented and compared with industry specifications. These Records are provided to the Customer as part of the service for as found and as built when the job is done, which is required for compliance with OSHA 29CFR1910.119 Process Safety Management, Mechanical Integrity element.

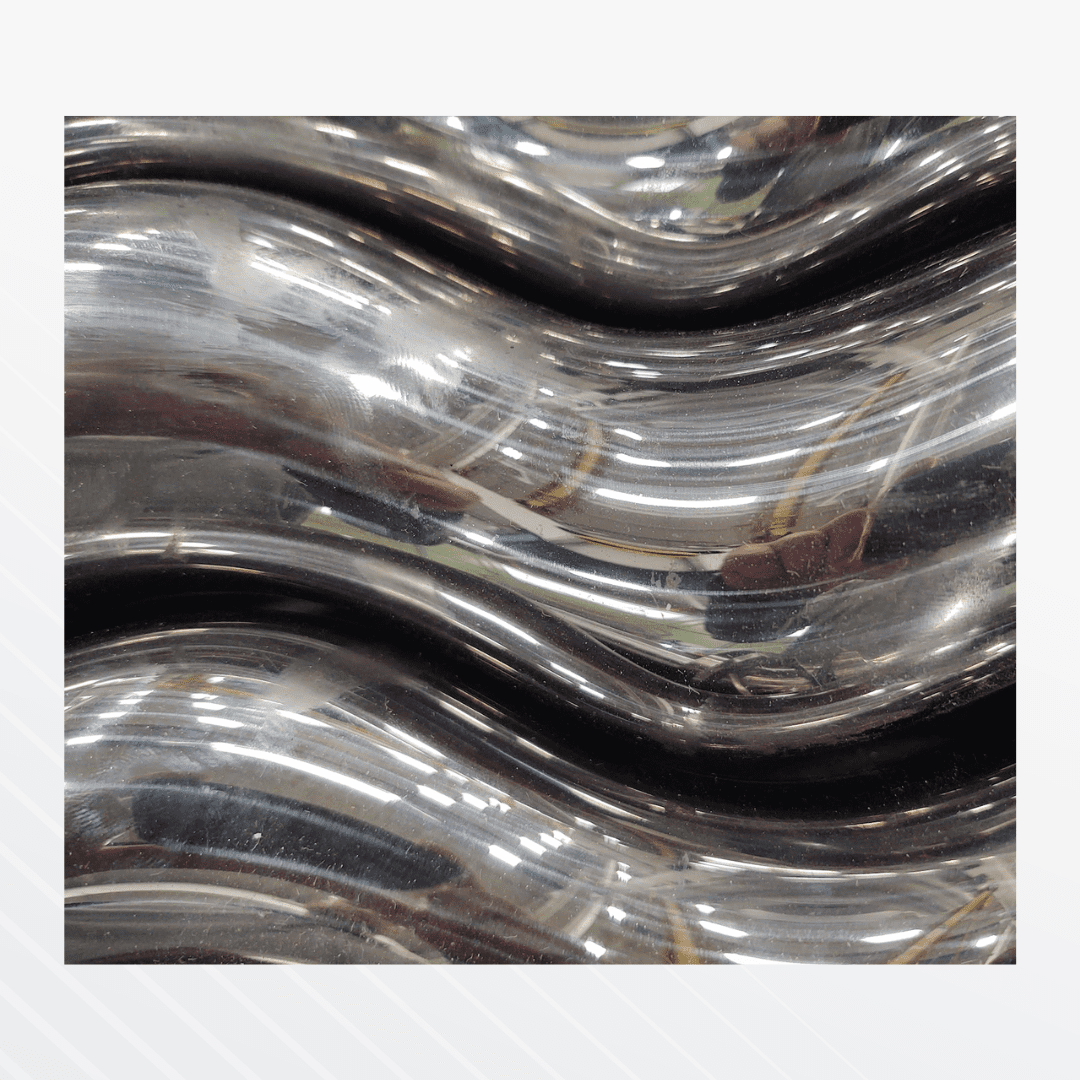

Friction creates heat, causing cavitation and robs equipment of energy causing the equipment to run harder, fail more often and creates more damage. We provide surface finishing and coating services using aerospace, motor sports and similar technology to improve your pump or fluid handling equipment to maximize efficiency at a fraction of the cost of the part being treated.

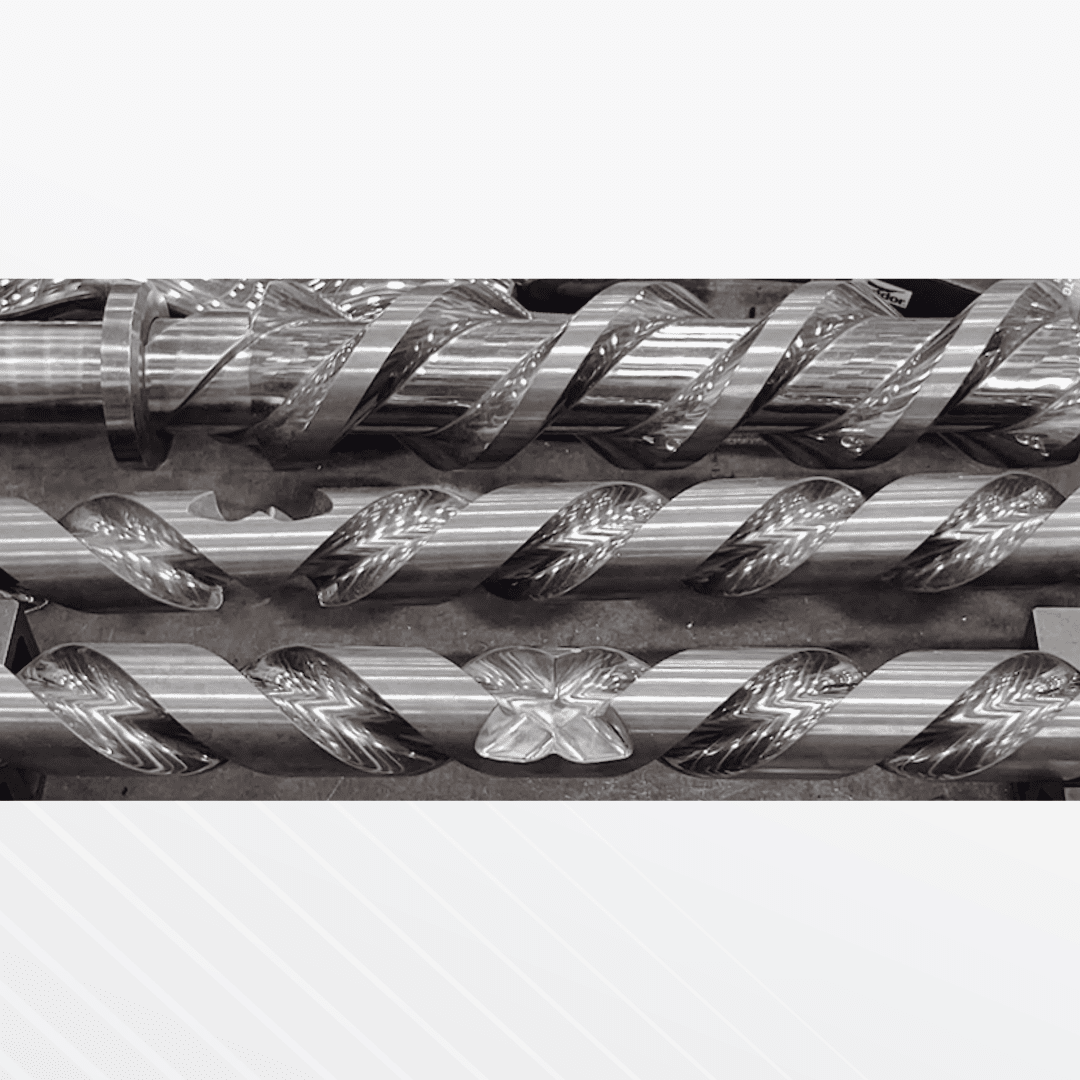

Reproduce, refinish and repair pump, turbine and similar shafts with a variety of different damage bringing back to specifications and improving their design better than OEM for a longer, lower cost operating run for a fraction of the cost of new.

Refinish, repair damage on shafts, impellers, pump cases, wear rings and other industrial equipment that would typically be thrown away can be repaired back to specifications and better than OEM for longer and lower cost operating run for a fraction of the cost of new.

Deep cryogenic heat treatment will strengthen steel making it tougher, more damage resistant, vibration resistant and lowering operating costs.

The technology used for repairs, reliability improvements can be used across a wide range of equipment and industries. If you have a problem with high operating costs, frequent repairs or high cost of repairs due to extensive damage, we can help you apply only the most cost effective solutions for your problem.

We have over 20 years of experience in reliability, root cause analysis, failure modes and similar investigation, repair and reliability strategies. If you have a problem with high operating costs, frequent repairs or high cost of repairs due to extensive damage, we can help you apply only the most cost effective solutions for your problem by performing a thorough analysis of the operating conditions, equipment design and making recommendations to solve these problems.

Customer

Thank You!